What are the Advantages of Stainless Steel Forged Fittings?

Stainless steel forged fittings have to additionally resist the capacity of corrosion and rust from the specific media in the gadget and the outside environmental situations. Generally, stainless steel forged fittings are used in maximum hydraulic and instrumentation structures due to their excessive pressure necessities or corrosive situations. Though plastics normally have a higher resistance to corrosion than metals, their relatively low electricity and durability cause them to less appropriate for hydraulic structures and the majority of instrumentation applications.

Metal fittings are basically product of carbon metallic, chrome steel, other special alloys or from time to time brass. For the purposes of this paper we are that specialize in carbon and stainless.

These metals are sturdy and sturdy, and might withstand excessive pressures and have high-quality heat resistance. Carbon steel fittings can face up to temperatures from -54°C (-sixty five.2°F) to 260°C (500°F) and are an alloy of iron, carbon other metals for excessive strength and sturdiness.

Stainless metal has superior resistance to chemicals and corrosive environments. Stainless steel threaded fittings face up to a typical temperature range from -254°C (-425.2°F) to 649°C (1200.2°F) and possess splendid corrosion resistance properties. Therefore, the traits of stainless make it a quite suitable fitting cloth for programs where the internal fluid or outside environment is subjected to excessive warmness and/or corrosive conditions.

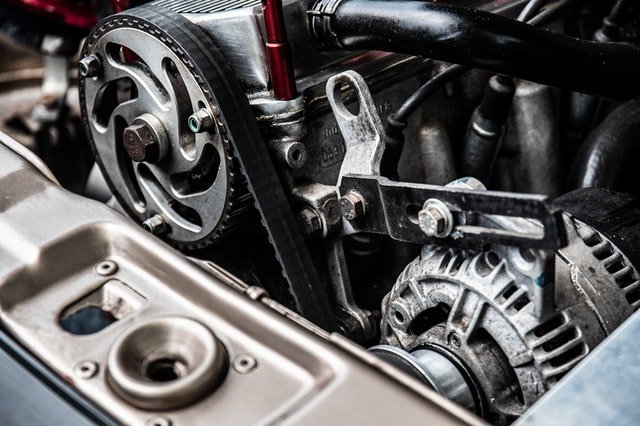

Forged Fittings VS Brazed: The Difference

Stainless steel forged fittings

Stainless steel forged fittings are made from one piece of metal, which allows them to be produced with less fabric presenting a more compact layout and smaller wrench flat. Most solid fittings are made using a warm forging manner which heats the steel above its recrystallization temperature, presenting for the annealing manner to achieve growth of recent grains inside the metallic with out phase trade.

In different phrases, warm forging is a metallic shaping manner which takes a malleable metal component, inclusive of a billet or other metal workpiece and heats as much as approximately seventy five% of its melting temperature. It is then worked, or basically molded, to a predetermined shape in a die.

Brazed Fittings

Brazed fittings are made from multiple, pre-machined components that are blended collectively, ensuing in a completed component. Though the brazing manner can permit for fittings with a few customization while combining multiple components, they may be liable to fatigue on the joints. Most brazed fittings are made with the aid of furnace brazing, that may generate a massive range of components on a non-stop belt in a controlled warmth cycle and atmosphere.

However, extra steps which includes making sure very near suits are vital to facilitate the capillary action inside the brazing procedure and secondary aspect elements are annealed for the duration of the manner. In addition, provisions should be made in the design technique for the location and match of the brazed additives.

Advantages of Stainless Steel Forged Fittings VS Other Processes

- Due to the tight grain structure, a forging is mechanically stronger than a casting

- Unlike castings, forgings are not prone to cavities, cold pour troubles, porosity or shrinkage

- Castings normally require extra steeply-priced alloys to attain the high electricity required for maximum stainless steel forged fittings

-

The tight grain structure of forgings provides greater wear resistance and isn’t so tough as to be much more likely to grow to be brittle in contrast to castings, permitting the cast becoming to withstand better pressures, extra excessive situations and revel in an extended provider life than a casted becoming.